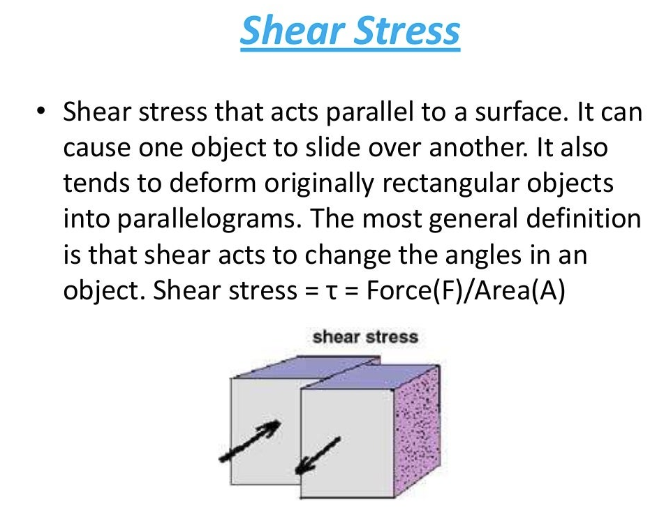

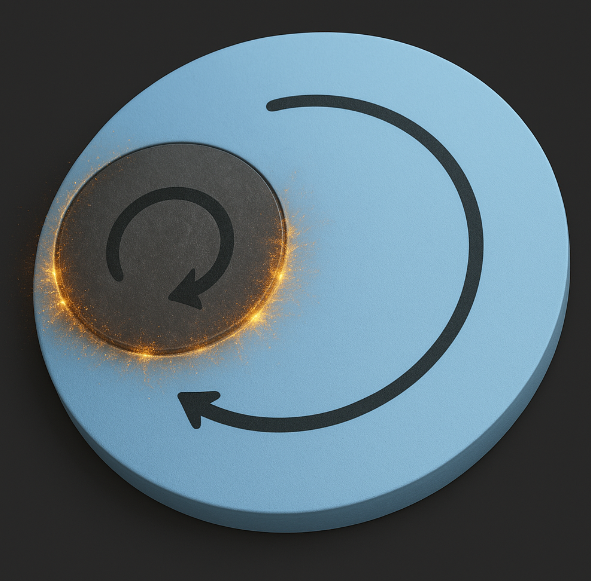

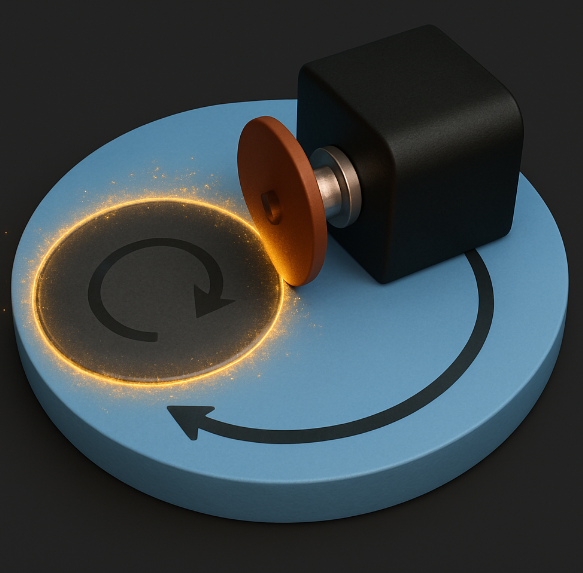

Shear stress occurs when two bodies move/slide relative to each other, sure sounds like the most basic application of friction.  Friction, resistance, induction. All happens when there is relative motion between two disjoint bodies. Even mister Onestone's general relativity equation has shear stress terms in it. Friction IS the magic force/interaction/equation of how anything interacts and exchanges momentum and energy. Now lets continuously exchange rotational momentum using friction. How? Insert a smaller disc within a larger disc and start spinning it, the friction will impart torque onto the larger disc.  As long as there is a constant relative velocity between the two discs there will be a constant torque acting on the bigger disc ie. a constant momentum exchange due to F=ma. So the whole assembly will not only keep spinning but be under a constant rotational acceleration, but the kicker is the fact the smaller disc is off center meaning it will be dragged ALONG by the larger disc and thus they will never find equilibrium in their velocity. But how do you provide the constant driving power to keep the small disc spinning in the rotating frame? Well you could add a motor in the rotating frame and place it exactly above the axis of rotation. This eliminates any back torque/force too.  So a constant power input of P = F*v gives you a constant torque a constant acceleration or put simple a constant exchange of angular momentum. Now for the skeptics. What if you allowed it to accelerate to some arbitrary angular velocity and decided to extract this rotational power. The output would be P_output=F(constant)*v(variable). The output thus depends on the variable RPM of the large disc you wish to extract power at. Note the INTERNAL rpm of the motor does NOT change it keeps pushing along that internal disc at the same RPM the entire way. The other interesting question is, is the internal motor even needed at all with some simple gearing setup.

|

Author

Topic: Will it spin? (Read 4471 times)

Author

Topic: Will it spin? (Read 4471 times)